Table of Contents

What is Switching? What are the Types?

It is the process of activating the loads existing in the system to meet the reactive power needs of the enterprises. This activation process can be done in two different ways in compensation. The first of these is the switching type made with compensation contactors, which are electromagnetic switching elements called “Classical Switching“. Second one is called “Thyristor Switching” which is the switching made with SVC driver and static contactors.

Classical Switched Compensation System

Mechanical switching is a switching method used in compensation systems. In these systems, capacitor banks or coils are activated and deactivated via mechanical switches. Mechanical switches can be considered as switches that can be manually turned on and off to balance the reactive power.

Compensation contactors are used for the switching process of capacitors and shunt reactors in compensation panels. Compensation capacitors draw a starting current just like synchronous, asynchronous motors. This excessive current draw that occurs at take-off can damage many elements used in the compensation panel. For this reason, compensation contactors are manufactured in a way that can withstand very large currents.

Thyristor Switched Compensation System

Thyristor, especially used in power electronics circuits, is a semiconductor switching element and has a very fast on-off feature. Thanks to the thyristor SVC drivers and static contactors developed by Grup Arge, it becomes possible to produce solutions in enterprises where there are fast loads and cannot be produced with contactor systems.

In thyristor systems, since the capacitors are activated at zero transitions, the obligation to wait for discharge times is eliminated. Moreover, since the current drawn when the capacitors are first activated is minimum, they can be switched on and off at a high speed. Thus, the service life and power quality of capacitors and switching elements are positively affected. In addition, panel maintenance costs are also minimized.

Thyristor Controlled SVC Drives

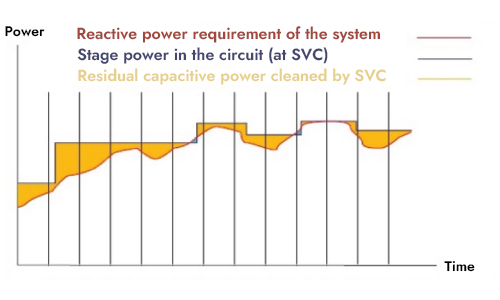

Smart SVC System is a new system developed after the classical compensation systems made with capacitor/reactor stages, capacitive characteristic loads and fast changing reactive loads could not fully respond to today’s enterprises, which have become widespread. The system consists of a reactive power control relay and a thyristor drive that can activate both capacitors and shunt reactors.

SVC load drivers and monophase shunt reactors connected to each phase are switching elements that enable precise compensation even at low powers by activating as much as the system needs.

In the Smart SVC system, the shunt reactors can be adjusted in 3000 steps in total, each step can be adjusted in 1000 steps by triggering their power at certain angles by thyristors. SVC Load Drives are designed to drive 3 monophase shunt reactors. In this way, the power of these reactors, each of them is connected to a separate phase, is controlled independently and in a way to provide the desired power.

Since the switching process in the Smart SVC system is performed with thyristors, the response can be generated in 20 ms.

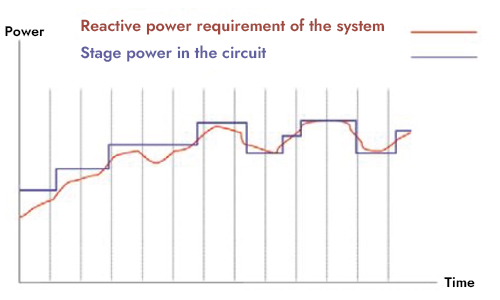

Response of Classical Relays to the System

Smart SVC’s Response to the System

Thyristor Controlled Static Contactors

Since the load change is very fast in enterprises with fast loads (spot welding, crane, etc.), power contactors cannot respond quickly enough to the reactive need. For this reason, static contactors are used instead of power contactors in enterprises with fast loads.

Capacitive static contactors prevent high switching currents by switching at the moment when the capacitor voltage and bus voltage are equalized. In addition, the capacitor switches very quickly without waiting for the capacitor discharge time to meet the reactive needs of fast loads.

Semiconductor circuit elements (thyristors, diodes) within static contactors are negatively affected by sudden changes in current and voltage. Some measures are taken in the manufacture of static contactors to protect semiconductor elements from sudden voltage changes. However, it is necessary to connect a low voltage surge arrester to the input of the compensation panel to protect the semiconductors in case of overvoltage surges that may occur in cases such as lightning strikes or power failure.

Sudden current changes that may occur during the switching of capacitors also damage semiconductors. In order to prevent this situation, two current limiting reactors or one harmonic filter should be connected for each of the static contactors to limit overcurrent increases.